Types of MDF for Cabinet Doors: Best Mdf For Cabinet Doors

/cabinet-refacing-demystified-1822044v2-29c0506ee7014a54a7473d9a5d85b149.jpg)

Choosing the right MDF (Medium-Density Fiberboard) for your cabinet doors is like choosing the right superhero for the job – you wouldn’t send Superman to fight a financial crisis, would you? (Unless he’s secretly a financial whiz, which, let’s be honest, is entirely possible.) Different MDF types have different strengths and weaknesses, making some better suited for certain applications than others. Let’s dive into the fascinating world of MDF and find your perfect cabinet door match.

MDF Types and Their Properties

The world of MDF isn’t as simple as “MDF” and “not MDF.” There are several types, each with its own personality (and density!). Choosing the right one depends on factors like your budget, the humidity in your kitchen (seriously, a damp kitchen can be a MDF’s worst nightmare), and the overall style of your cabinets.

| Type | Density (lbs/ft³) | Moisture Resistance | Cost |

|---|---|---|---|

| Standard MDF | 45-55 | Low | Low |

| Moisture-Resistant MDF (MR MDF) | 48-60 | Medium | Medium |

| Exterior-Grade MDF (or Exterior-Use MDF) | 55-70 | High | High |

Advantages and Disadvantages of Different MDF Types

Let’s break down the pros and cons of each MDF type, because even superheroes have kryptonite (or, in this case, water damage).

Standard MDF: Think of it as the friendly neighborhood MDF – it’s readily available and affordable. However, it’s not exactly a fan of humidity, so it’s best kept away from areas prone to moisture, like bathrooms or particularly humid kitchens. It’s great for interior cabinet doors in dry environments.

Moisture-Resistant MDF (MR MDF): This is the superhero of the MDF world, possessing enhanced resistance to moisture. It’s a solid choice for kitchens and bathrooms, but it’s not invincible. Prolonged exposure to extreme humidity can still cause issues.

Exterior-Grade MDF: This is the heavy hitter, designed to withstand the elements. Think of it as the MDF equivalent of a seasoned adventurer who has faced every kind of weather. It’s perfect for outdoor applications or areas with extremely high humidity, but it comes with a heftier price tag.

Performance of MDF Types Under Different Conditions

Now for the moment of truth: how do these MDF types perform under pressure? (Pressure, in this case, meaning humidity and temperature.) Imagine a cabinet door showdown – who will come out on top?

| MDF Type | High Humidity | High Temperature | Low Temperature |

|---|---|---|---|

| Standard MDF | Significant swelling and warping possible | Slight expansion | Slight contraction |

| MR MDF | Minimal swelling, some warping possible | Slight expansion | Slight contraction |

| Exterior-Grade MDF | Minimal to no noticeable effects | Minimal expansion | Minimal contraction |

Factors Affecting MDF Cabinet Door Quality

_Page_2.png)

So, you’ve decided to grace your kitchen with the glorious presence of MDF cabinet doors. Excellent choice! But not all MDF is created equal. Think of it like choosing a wine – you wouldn’t just grab the cheapest bottle, would you? (Unless you’re on a particularly tight budget, in which case, hey, we don’t judge). The quality of your MDF cabinet doors hinges on several key factors, and understanding them will save you from a future filled with wobbly doors and chipped paint.

The lifespan and aesthetic appeal of your MDF cabinet doors depend heavily on the manufacturing process and the materials used. A poorly constructed door is a recipe for disaster – think of it as a culinary catastrophe involving slightly less flour and significantly more tears. Let’s delve into the specifics, shall we?

Core Density and its Impact on Door Durability

The density of the MDF core is paramount. Think of it as the backbone of your door – a flimsy backbone leads to a flimsy door. Higher density means greater strength and resistance to warping, sagging, and general door-related shenanigans. Lower density MDF, on the other hand, might seem cheaper initially, but it’s a gamble that could leave you with doors that resemble deflated balloons after a few years. Imagine the disappointment! A good rule of thumb is to opt for a higher density MDF, especially for larger doors that will bear more weight.

Finish Quality: The Face (and Longevity) of Your Doors

The finish is the final frontier, the cherry on top of your cabinet door sundae (with extra sprinkles, naturally). A high-quality finish protects the MDF from moisture, scratches, and general wear and tear. A poorly applied finish, however, is an open invitation for disaster. Think peeling paint, water damage, and an overall aesthetic that screams “I regret this decision.” Consider the type of finish: paint offers a durable and customizable option, while veneer adds a touch of elegance and a natural wood grain look (though it might be more susceptible to scratches). A properly applied finish, regardless of type, is key to longevity.

Edge Banding: The Unsung Hero of MDF Cabinet Doors

Edge banding, that often-overlooked detail, plays a crucial role in the overall durability and water resistance of your MDF cabinet doors. Think of it as the door’s protective armor. Poorly applied edge banding can lead to moisture seeping into the core, causing swelling and warping. This is a recipe for cabinet door chaos. Look for doors with high-quality edge banding that is properly sealed to prevent moisture absorption.

Selecting High-Quality MDF: A Step-by-Step Guide

Choosing the right MDF can feel like navigating a minefield, but with the right approach, it can be surprisingly straightforward. Here’s a step-by-step guide to help you conquer the MDF mountain:

- Define your budget: Know how much you’re willing to spend. This will help narrow down your options.

- Determine your needs: Consider the size and weight of the doors, the level of moisture exposure, and the desired aesthetic.

- Research MDF suppliers: Compare prices, quality, and customer reviews.

- Check the density: Opt for higher-density MDF for greater durability.

- Examine the finish: Look for a smooth, even finish with no imperfections.

- Inspect the edge banding: Ensure it’s securely applied and sealed.

- Request samples: Compare different options before making a final decision. Don’t be shy!

The Impact of Different Finishes on Appearance and Longevity

The finish you choose drastically alters the look and feel of your cabinet doors. Paint offers a wide range of colors and finishes, from sleek matte to glossy perfection. It’s also relatively easy to maintain and repair. Veneer, on the other hand, provides a more natural look, but it’s generally more expensive and susceptible to scratches. The choice depends on your personal preference and budget. Remember, a well-applied finish, regardless of type, is your best bet for long-lasting beauty.

MDF Cabinet Door Design and Construction

So, you’ve chosen MDF for your cabinet doors – excellent choice! It’s versatile, relatively inexpensive, and can be shaped into practically anything your heart desires (within reason, of course. We’re not promising you can carve a life-sized T-Rex). Now let’s talk design and construction. Get ready to unleash your inner cabinet-making guru!

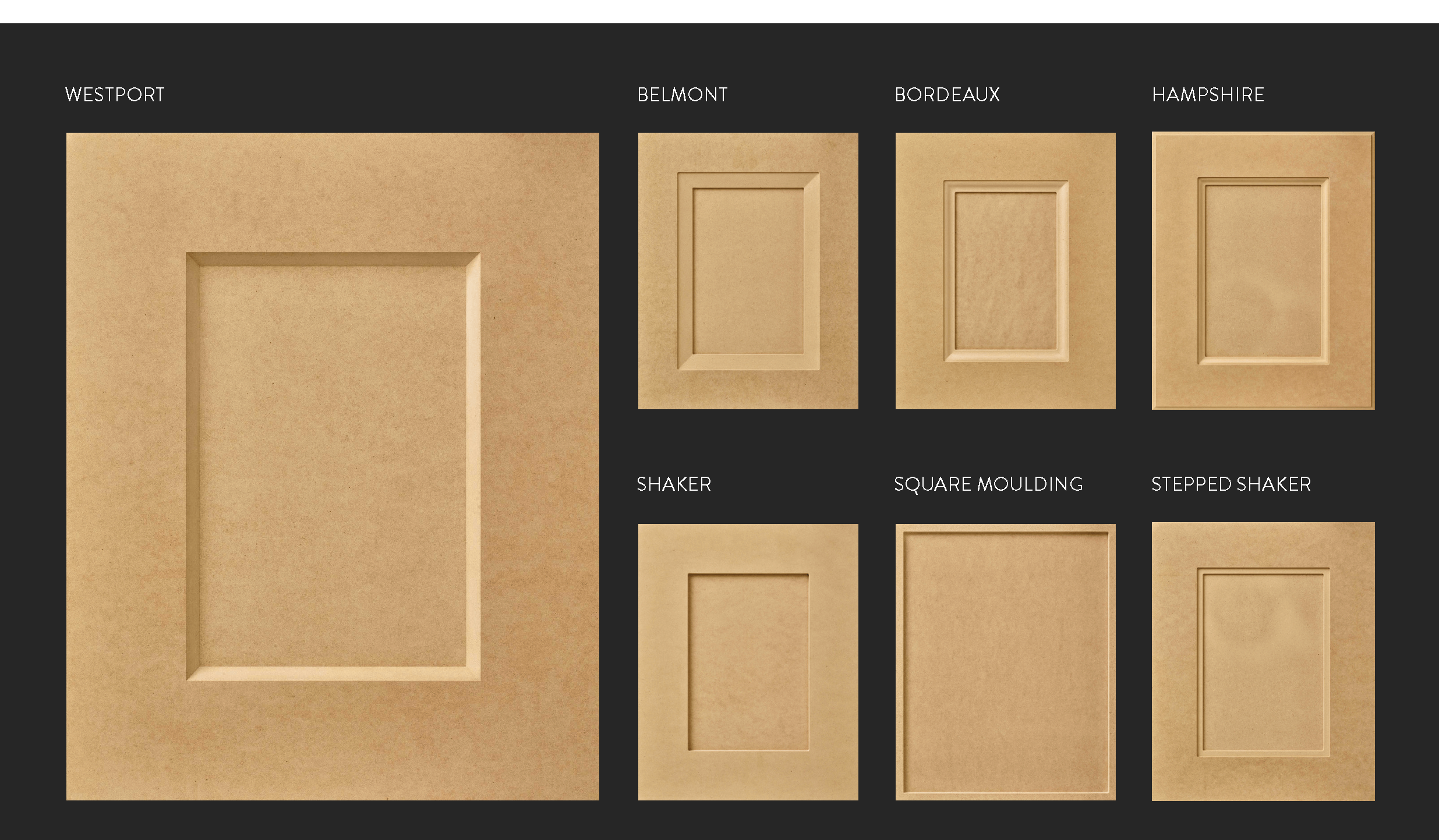

MDF Cabinet Door Styles

The beauty of MDF is its adaptability. You’re not limited to a single, boring style. Let’s explore some popular options, presented in a way that’s both informative and (dare we say) mildly entertaining.

| Style | Description | Advantages | Disadvantages |

|---|---|---|---|

| Raised Panel | Features a central panel that’s raised above the surrounding frame. Think classic, elegant, and slightly fancy. Imagine a perfectly pressed flower, only it’s wood. | Adds depth and visual interest; timeless appeal; can be painted or stained. | More complex to construct than flat panel doors; requires more precise joinery. |

| Flat Panel | Simple, clean lines; a single, flat panel. Modern, minimalist, and perfect for a sleek kitchen. | Easy to construct; cost-effective; versatile styling options. | Can appear less interesting than raised panel doors; prone to showing imperfections in the finish. |

| Shaker | Features a recessed center panel framed by a raised border. A happy medium between raised panel and flat panel – a Goldilocks of cabinet door styles. | Classic yet contemporary; relatively easy to construct; durable. | Requires careful attention to detail during construction; slightly more complex than flat panel doors. |

| Beaded/Inset | A raised panel with a decorative beading around the edges. A little bit of extra flair for your cabinets. | Adds decorative detail; visually interesting; can create a custom look. | More complex to construct than flat panel doors; requires specialized tools and skills. |

Constructing Durable MDF Cabinet Doors

Building a sturdy MDF cabinet door isn’t rocket science (though it might feel like it at times). The key is precision and the right tools. Properly routed edges and carefully applied finishing are your best friends. Think of it as a delicate dance between strength and beauty. A poorly constructed door is a sad door, and nobody wants a sad door.

Creating Custom MDF Cabinet Doors, Best mdf for cabinet doors

Let’s say you want a door shaped like a giant pineapple (we’re not judging). Here’s the general process:

1. Material Selection: Choose your MDF – thickness depends on the door size and desired strength. Thicker is generally better for larger doors.

2. Design and Cutting: Create your design (pineapple, perhaps?). Use CAD software or a good old-fashioned pencil and paper. Then, carefully cut the MDF using a CNC router or a jigsaw (for those with a steadier hand).

3. Finishing: Sand the edges smooth, apply primer, and then paint, stain, or veneer, depending on your desired aesthetic. Multiple coats are your friend here.

4. Hardware Installation: Attach hinges and handles. Make sure everything lines up perfectly; otherwise, your pineapple door might end up looking slightly… lopsided.